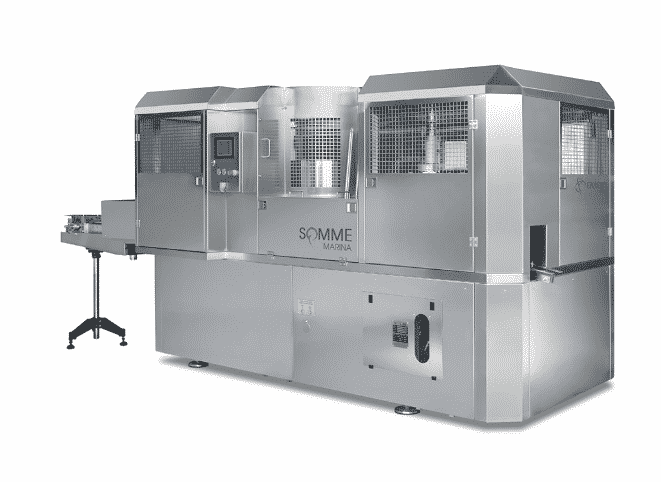

Autoclaves

Our machine can be operated in accordance with all kinds of packaging. Plastic-glass containers / jars / boxes / small bags / big bags etc. Sterilisation and pasteurisation process for all these products are carried out without any errors.

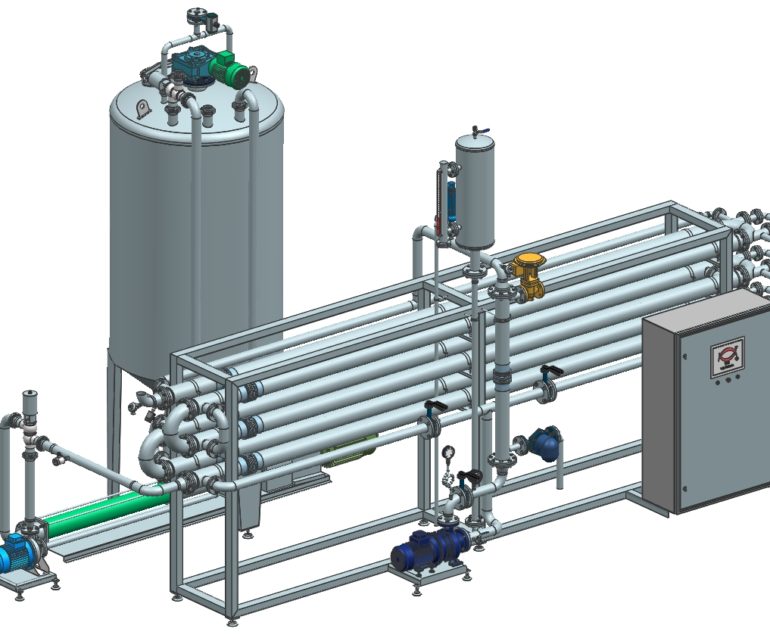

All kinds of cycles (operation) are completed according to the automatic settings stored in a programmer equipped with a PLC and equipment. This system also records all operations on a USB stick with a recorder. If desired, this system can also be transferred to a PC in your business. Many recipes can be prepared according to product and packaging types. Our autoclave is manually closed after the baskets are loaded manually or optionally in all models and locked by a pneumatic pressure cylinder. This locking process is also controlled by sensors. The pump is activated automatically (according to the recipe) after filling the ballast level or the first cycle water. Pump, filter, Water passed through equipment such as heat exchangers is pulverised on the product from 5 regions with specially produced nozzles. (sprayed) Throughout the entire operation, heat, pressure, counter pressure is activated automatically according to the recipe cycle prepared, thus ensuring that all products are pasteurised or sterilised to the same standard.